Natural Gas

Innovative chemical solutions for H₂S removal.

Instantly sweetened gas, reduced flare, and increased profits.

The Knockout Process

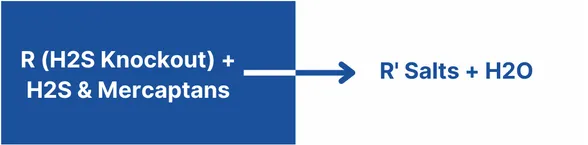

H₂S Knock-Out converts H₂S instantly and irreversibly into a non-toxic sulfur salt and water:

H₂S Knockout has earned the approval of major producers and midstream companies, and is a trusted solution utilized by a wide range of professionals in the natural gas industry.

H₂S Knockout has earned the approval of major producers and midstream companies, and is a trusted solution utilized by a wide range of professionals in the natural gas industry.

Applications

Can be injected under pressure and utilizing a static mixer.

The reaction is instantaneous in the gaseous phase and the separation of newly formed Sulfate salts occurs very fast.

In multi- phase lines H₂S Knockout will remove H₂S from all phases and the by-product will stay in the produced water phase.

Advantages

The reaction is irreversible and the result

is non-toxic aqueous salts that are easily separated in the produced water process.

The amount of H₂S Knockout required to remove H₂S from any system is up to 5 times less than that of a triazine based scavenger.

Eliminates formations of solids, corrosions, and mitigates safety concerns associated with triazine and formaldehyde based treatments.

Greater efficiency leading to reduced costs.

Applications

Can be injected under pressure and utilizing a static mixer.

The reaction is instantaneous in the gaseous phase and the separation of newly formed Sulfate salts occurs very fast.

In multi- phase lines H₂S Knockout will remove H₂S from all phases and the by-product will stay in the produced water phase.

Advantages

The reaction is irreversible and the result

is non-toxic aqueous salts that are easily separated in the produced water process.

The amount of H₂S Knockout required to remove H₂S from any system is up to 5 times less than that of a triazine based scavenger.

Eliminates formations of solids, corrosions, and mitigates safety concerns associated with triazine and formaldehyde based treatments.

Greater efficiency leading to reduced costs.

Pages

Case Studies

Follow US

Copyright H₂S Knockout 2023 . All rights reserved

Pages

Case Studies

Follow Us