Crude Oil: Case 2

Oil Test Trial

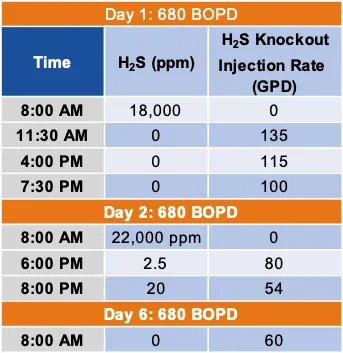

Before Knock-Out Treatment

300 gallons/day of a Triazine H₂S scavenger into 680 barrels of oil per day

Lowest treatment level was 15ppm of H₂S at the sales point

Client forced to circulate oil every few days due to failed BS&W specs.

H₂S Knock-Out Treatment

Injection point of H₂S Knockout was started on the oil dump of the heater treater.

The oil went to a sales tank before reaching the sales LACT and the H₂S system monitors (~150 ft from injection point)

On sixth day of treatment, the customer had no rejected oil due to failed BS&W and has stopped circulation.

Takeaways

Cost savings of $60,000/month on chemical

Company no longer needed to circulate oil due to failed BS&W

Takeaways

Cost savings of $60,000/month on chemical

Company no longer needed to circulate oil due to failed BS&W

Want access to the full case study? Contact our team of experts.

Want access to the full case study? Contact our team of experts.

View Related Case Studies

Pages

Case Studies

Follow US

Copyright H₂S Knockout 2023 . All rights reserved

Pages

Case Studies

Follow Us