Crude Oil: Case 1

Crude Oil Tank Battery Test

Tailgate Testing

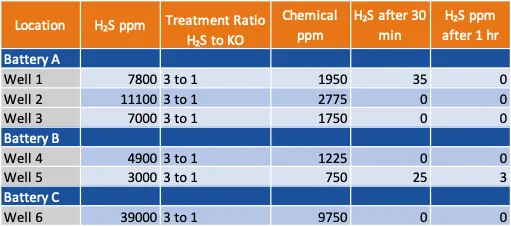

Three tank batteries consisting of 6 different wells ranging from 3000 to 39,000 ppm H₂S.

H₂S Knockout was injected on inlet of each tank battery

H₂S levels were tested on outlet of tank batteries to sales

Customer's pipeline spec through the LACT unit were achieved and maintained for the duration of the test with no increases to injection rates.

Takeaways

Treatment ratio of 3 to 1 H₂S to chemical achieved H2S target in less than 30 minutes

Implementation of Knockout maintained H₂S Spec in crude oil over the entire 4 month treatment program

All batteries achieved <5ppm H₂S in less than an hour

Takeaways

Treatment ratio of 3 to 1 H₂S to chemical achieved H2S target in less than 30 minutes

Implementation of Knockout maintained H₂S Spec in crude oil over the entire 4 month treatment program

All batteries achieved <5ppm H₂S in less than an hour

Want access to the full case study? Contact our team of experts.

Want access to the full case study? Contact our team of experts.

View Related Case Studies

Pages

Case Studies

Follow US

Copyright H₂S Knockout 2023 . All rights reserved

Pages

Case Studies

Follow Us