Crude Oil: Case 3

Midstream Company's Pipeline

Tailgate Testing

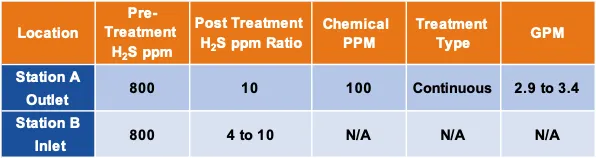

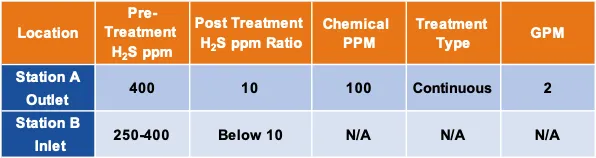

A midstream company is unable to sell oil with 800 ppm H₂S from 15,000 barrels of crude in a 24-inch mainline.

Knockout submitted a proposal of 2.9 to 3.4 gal/min into the 24-inch mainline.

The injection was 75 yards upstream of two mainline pumps before leaving the station.

The H₂S level at the discharge of the station was reduced to 10ppm after treatment with Knockout.

At the inlet to the next station, 65 miles away, the H₂S levels remained below 10 ppm.

Day 1

Day 2

Takeaways

H₂S levels at discharge of the station were reduced to below 10 ppm after treatment

The H₂S levels remained below 10 ppm at the inlet station (65 miles away), showing the reaction is irreversible

The H₂S to chemical ratio that achieved below 10 ppm H₂S was 8:1

Takeaways

H₂S levels at discharge of the station were reduced to below 10 ppm after treatment

The H₂S levels remained below 10 ppm at the inlet station (65 miles away), showing the reaction is irreversible

The H₂S to chemical ratio that achieved below 10 ppm H₂S was 8:1

Want access to the full case study? Contact our team of experts.

Want access to the full case study? Contact our team of experts.

View Related Case Studies

Pages

Case Studies

Follow US

Copyright H₂S Knockout 2023 . All rights reserved

Pages

Case Studies

Follow Us