Natural Gas Case Study

Midstream Company's Pipeline

Conventional Triazine Treatment

Incumbent treating 20,000ppm H₂S with 750 gallons per day of a 40% triazine based chemical

Triazine was causing significant dithiazine solids in the system

Client was interested in Triazine alternatives after multiple system cleanouts

H₂S Knockout Treatment

System was cleaned prior to the test trial with Knockout

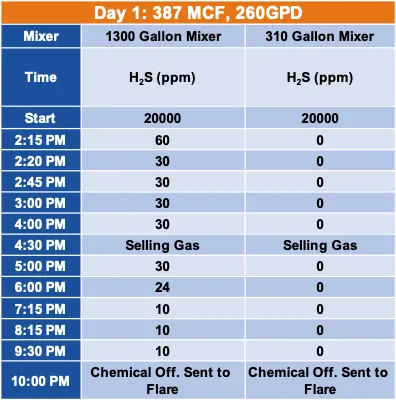

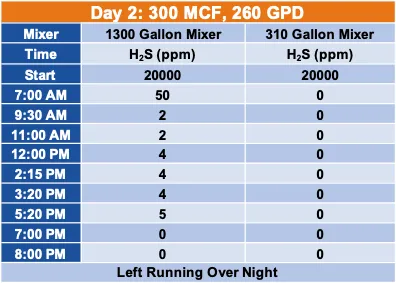

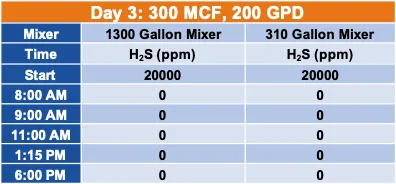

A 1300-gallon mixer and a 310-gallon mixer were installed in series

The outlet of the 310-gallon mixer departs to the sales line

H₂S levels were monitored on the discharge of both mixers

Takeaways

Cost savings of $120,000/month on chemical

Cost savings of $10,000 -$12,000/month on system cleanouts and down time

200 GPD of H₂S Knockout resulted in 0ppm H₂S

Knockout uses 550 gallons less per day than 40% Triazine with no dithiazine build-up in the system

Takeaways

Cost savings of $120,000/month on chemical

Cost savings of $10,000 -$12,000/month on system cleanouts and down time

200 GPD of H₂S Knockout resulted in 0ppm H₂S

Knockout uses 550 gallons less per day than 40% Triazine with no dithiazine build-up in the system

Want access to the full case study? Contact our team of experts.

Want access to the full case study? Contact our team of experts.

Pages

Case Studies

Follow US

Copyright H₂S Knockout 2023 . All rights reserved

Pages

Case Studies

Follow Us